MXB-JOML slidplade til fremstillingsindustrien

Cat:Selvsmørende slidplade/styreskinne

MXB-JOML selvsmørende slidplader er designet til at minimere friktion og forlænge levetiden i industrielle applikationer. Produktet er lavet af en ...

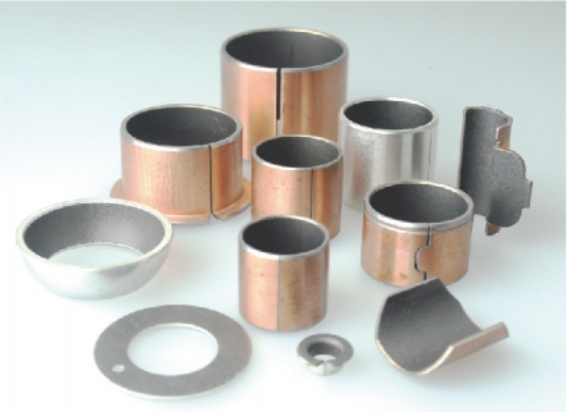

Se detaljerThe interference fit of oil-free bearings means that during the installation process of oil-free bearings, the outer diameter is designed to be slightly larger than the inner diameter of the seat hole, which generates a certain amount of stress after assembly. This design aims to maintain a high roundness of the inner circle of the bearing and secure the bearing more firmly, effectively preventing slippage and wear. The design and application of oil-free bearing interference ensures the stability and reliability of the bearings under harsh working conditions.

Advantages of interference fit

Oil-free bearings, such as the SF-1 series, have significant features such as no need for lubrication, easy maintenance, and long service life. Therefore, they are widely used in various types of mechanical equipment, especially in situations with low speed, heavy load or difficult maintenance.

Calculation of interference

The interference is divided into minimum and maximum values, which are calculated from the maximum and minimum values of the outer diameter of the bearing and the inner diameter of the seat hole.

The calculation formula for interference is as follows:

Example:

SF-1 series SF-1·2015 (standard product), matching seat hole Dh=23H7+0.021, find the interference amount after assembly.

Calculate:

It is known that the maximum bearing outer diameter Max=23.075 and the minimum bearing outer diameter Min=23.035;

The maximum value of the inner diameter of the seat hole is Max=23.021, and the minimum value of the inner diameter of the seat hole is Min=23.00.

δmin=minimum bearing outer diameter Dmin-maximum seat hole inner diameter DHmax=23.035-23.021=0.014

δmax=maximum bearing outer diameter Dmax-minimum seat hole inner diameter DHmin=23.075-23.000=0.075

Therefore, the interference amount after assembly δ=0.014~0.075mm

The following points need to be noted for the interference fit of oil-free bearings:

In addition, attention should also be paid to the inspection of interference fitting parts before assembly, such as interference amount, verticality deviation, mating surface condition, etc., to ensure smooth assembly and normal use of the bearing.

MXB-JOML selvsmørende slidplader er designet til at minimere friktion og forlænge levetiden i industrielle applikationer. Produktet er lavet af en ...

Se detaljer

MXB-JTGLW selvsmørende styreskinner giver modstand og reducerer friktion, hvilket sikrer forlænget holdbarhed og forbedret ydeevne. Dette produkt h...

Se detaljer

MXB-JGLX selvsmørende styreskinner dækker flere egenskaber såsom høj slidstyrke, høj temperaturbestandighed, korrosionsbestandighed osv., og kan gi...

Se detaljer

Cirkulære guider bruges ofte i bilpanelforme og store stemplingsforme. Formbund- og aflæsningspladestyrene bruger normalt selvsmørende styrebøsning...

Se detaljer

MX2000-2 nikkel grafit dispergeret legering lejer er et nyt produkt blandt solide smørelejer. Sammenlignet med TF-1 har dette produkt karakteristik...

Se detaljer

SF-1X oil-free lubricating bearing is a rolled sliding bearing with steel plate as the base, spherical bronze powder sintered in the middle, and a mix...

Se detaljer

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

Se detaljer

SF-PK PEEK triple composite bearing is a novel sliding bearing, which consists of steel plate, copper powder layer, PTFE + filling material. The main ...

Se detaljer

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

Se detaljer

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

Se detaljer

Kontakt os